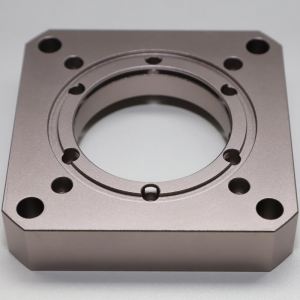

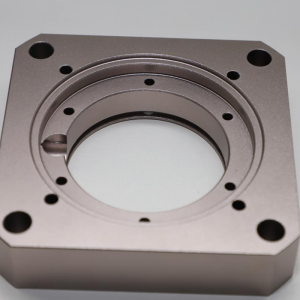

Precision Aluminium Machined Parts

CNC (Computer Numerical Control) machining yog cov txheej txheem tsim tawm: cov khoom yog tsim los ntawm kev tshem tawm cov khoom los ntawm cov khoom thaiv (hu ua ib qho dawb los yog dawb) siv ntau yam cutters.

Nws yog ib qho tseem ceeb sib txawv ntawm kev tsim khoom ntau dua li cov khoom siv ntxiv (3D luam ntawv) lossis molding (txhaj tshuaj molding) thev naus laus zis.Cov txheej txheem tshem tawm cov khoom cuam tshuam cuam tshuam rau CNC lub zog, kev txwv, thiab kev txwv tsim.Nyeem ntxiv hauv qab no.

Lub hauv paus txheej txheem CNC tuaj yeem muab faib ua peb kauj ruam.Peb cov engineers pib los ntawm kev tsim qauv CAD ntawm ib feem.Tus kws kho tshuab ces hloov cov ntaub ntawv CAD rau hauv CNC software (G-code) thiab teeb tsa lub tshuab.Thaum kawg, CNC machining system ua txhua yam kom tshem tawm cov khoom thiab tsim cov khoom nrog kev saib xyuas me ntsis.

Hauv qab no tsuas yog ob peb yam kev kho mob saum npoo uas peb tau siv rau peb cov khoom, yog tias koj xav tau lwm tus thov hu rau peb.Peb yuav tshuaj xyuas koj cov lus thov thiab cov lus teb rau koj.

Anodizing: anodizing feem ntau hais, nws yog txheej txheem uas hloov qhov saum npoo ntawm cov hlau tsis muaj hlau mus rau hauv corrosion-resistant, zoo nkauj, uas tsis yog-conductive oxide.Ntau hom xim tuaj yeem xaiv.

Sandblasting: qee zaum hu uaabrasive blasting, yog kev ua haujlwm ntawm kev quab yuam propelling kwj ntawmabrasivekhoom tiv thaiv ib tug nto nyob rau hauv siabsiabua smooth antxhibnto, roughen ib tug du nto, shape ib tug nto los yog tshem tawm ntocov kab mob

Polishing: Polishing yog tus txheej txheem ntawm kev tsim ib tug du thiab ci ntsa iab nto los ntawm rubbing los yog siv tshuaj kho mob, tawm hauv ib tug huv si nto nrog ib tug tseem ceeb xav txog specular.