Burrs yog ib qho teeb meem tshwm sim hauv kev ua hlau, xws li drilling, tig, milling, thiab ntawv hlau txiav...

Ib qho kev phom sij ntawm burrs yog tias lawv yooj yim txiav!Txhawm rau tshem tawm burrs, kev ua haujlwm thib ob hu ua deburring feem ntau yuav tsum tau ua.3 deburring thiab ntug xov ntawm precision qhov chaw tuaj yeem suav txog 30% ntawm tus nqi ntawm qhov tiav.Tsis tas li ntawd, kev ua haujlwm thib ob yog qhov nyuaj rau automate, yog li burrs tiag tiag dhau los ua qhov teeb meem nyuaj.

Yuav daws li casBURRS

1 Phau ntawv deburring

Qhov no yog ib txoj kev siv ntau dua thiab feem ntau siv, siv cov ntaub ntawv (cov ntaub ntawv phau ntawv thiab cov ntaub ntawv pneumatic), cov ntawv xuab zeb, siv cov xuab zeb, sib tsoo taub hau, thiab lwm yam ua cov cuab yeej pabcuam.

DisadvanCov cim npe: Tus nqi ua haujlwm yog kim, qhov ua tau zoo tsis yog siab heev, thiab nws yog ib qho nyuaj rau tshem tawm txoj kev hla qhov.

Cov khoom siv tau: Cov kev xav tau rau cov neeg ua haujlwm tsis siab heev, thiab nws yog qhov tsim nyog rau aluminium alloy tuag castings nrog me me burrs thiab cov qauv khoom yooj yim.

2 Tuag deburring

Deburring yog ua los ntawm kev siv lub tshuab tuag thiab xuas nrig ntaus.

Disadvantages: Nws yuav tsum tau ib tug npaum li cas ntawm tuag ( ntxhib tuag, nplua tuag) cov nqi tsim khoom, thiab tej zaum kuj yuav tsum tau ua ib tug shaping tuag.

Cov khoom siv: Nws yog tsim rau aluminium alloy tuag castings nrog yooj yim parting nto, thiab cov efficiency thiab deburring nyhuv yog zoo dua li cov ntawm phau ntawv ua hauj lwm.

3 Sib tsoo thiab deburring

Hom kev deburring no suav nrog kev vibration, sandblasting, rollers, thiab lwm yam, thiab tam sim no siv los ntawm cov nroj tsuag tuag-casting.

Qhov tsis zoo: Muaj qhov teeb meem uas qhov kev tshem tawm tsis huv heev, thiab cov txheej txheem tom ntej ntawm cov burrs residual los yog lwm yam kev tshem tawm yuav tsum tau ua.

Cov khoom siv: haum rau me me aluminium alloy tuag castings nrog cov khoom loj.

4 Frozen deburring

Siv cov cua txias kom sai sai rau cov burrs, thiab tom qab ntawd tshuaj tsuag qhov projectiles kom tshem tawm cov burrs.Tus nqi ntawm cov khoom siv yog hais txog 200,000 lossis 300,000;

Cov khoom siv: Haum rau txhuas alloy tuag castings nrog me me burr phab ntsa thickness thiab me me ntim.

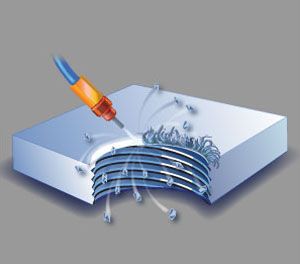

5 Kub blast deburring

Kuj hu ua thermal deburring, tawg deburring.Los ntawm kev taw qhia qee cov roj hluav taws xob rau hauv cov khoom siv hluav taws xob, thiab tom qab ntawd los ntawm kev ua ntawm qee qhov kev tshaj tawm thiab cov xwm txheej, cov roj tau tawg tam sim ntawd, thiab lub zog tsim los ntawm kev tawg yog siv los yaj thiab tshem tawm cov burr.

Qhov tsis zoo: cov khoom siv kim (ntau lab daus las), kev ua haujlwm siab rau kev ua haujlwm, kev ua haujlwm tsis zoo, kev phiv tshuaj (rusting, deformation);

Cov khoom siv tau: Feem ntau yog siv hauv qee qhov chaw ua haujlwm siab, xws li tsheb thiab aerospace precision qhov chaw.

6 Deburring ntawm engraving tshuab

Tus nqi ntawm cov cuab yeej tsis kim heev (txog kaum txhiab).

Cov khoom siv tau: Nws tsim nyog rau qhov chaw yooj yim qauv thiab yooj yim thiab tsis tu ncua deburring txoj hauj lwm.

7 Chemical deburring

Siv lub hauv paus ntsiab lus ntawm cov tshuaj tiv thaiv electrochemical, cov khoom ua los ntawm cov khoom siv hlau tuaj yeem raug txiav thiab xaiv deburred.

Cov khoom siv tau: haum rau sab hauv burrs uas nyuaj rau tshem tawm, haum rau cov burrs me me (thickness tsawg dua 7 xov hlau) ntawm cov khoom xws li lub cev twj tso kua mis thiab lub cev valve.

8 Electrolytic deburring

Ib txoj kev electrolytic machining rau tshem tawm aluminium alloy tuag-casting burrs los ntawm electrolysis.Electrolytic deburring yog tsim rau tshem tawm burrs nyob rau hauv zais qhov chaw ntawm txhuas alloy tuag castings, hla qhov los yog qhov chaw nrog complex duab.Kev ua haujlwm ntau lawm yog siab, thiab lub sijhawm deburring feem ntau tsuas yog ob peb feeb mus rau kaum vib nas this.

Qhov tsis zoo: Cov electrolyte yog corrosive rau qee qhov, thiab thaj tsam ntawm qhov burr ntawm qhov chaw kuj raug electrolysis, qhov saum npoo yuav plam nws cov luster qub, thiab tseem cuam tshuam rau qhov tseeb qhov tseeb.Aluminium alloy tuag-casting yuav tsum tau ntxuav thiab xeb-pov thawj tom qab deburring.

Cov khoom siv tau: Nws yog tsim rau kev deburring ntawm lub zog, txuas rods, valve lub cev thiab crankshaft roj hla qhov, nrog rau kev sib tw ntawm cov ces kaum ntse.

9 High-pressure dej dav hlau deburring

Siv dej ua ib qho nruab nrab, nws tuaj yeem siv nws lub zog cuam tshuam tam sim los tshem tawm cov burrs thiab flashes tsim tom qab ua tiav, thiab tib lub sijhawm, nws tuaj yeem ua tiav lub hom phiaj ntawm kev ntxuav.

Cons: Cov khoom siv kim

Cov khoom siv tau: feem ntau yog siv rau hauv plawv ntawm tsheb thiab hydraulic tswj tshuab ntawm kev tsim kho tshuab.

10 Ultrasonic deburring

Cov pa vibration sib tsoo yog qhov nyuaj los daws cov burrs xws li qhov.Cov txheej txheem abrasive txaus machining txheej txheem (ob txoj kev khiav) thawb lub abrasive los ntawm ob lub vertically opposite abrasive cylinders kom nws ntws rov qab mus rau hauv cov channel tsim los ntawm workpiece thiab fixture.Kev nkag thiab ntws ntawm abrasive mus rau hauv thiab los ntawm txhua qhov chaw uas raug txwv yuav ua rau muaj kev cuam tshuam abrasive.Lub extrusion siab yog tswj ntawm 7-200bar (100-3000 psi), haum rau txawv strokes thiab sib txawv lub sij hawm.

Cov khoom siv tau: Nws tuaj yeem lis 0.35mm microporous burrs, tsis muaj cov burrs thib ob yog tsim, thiab cov yam ntxwv ntawm cov kua dej tuaj yeem tswj txoj haujlwm nyuaj.

11 Abrasive flow deburring

Cov pa vibration sib tsoo yog qhov nyuaj los daws cov burrs xws li qhov.Cov txheej txheem abrasive txaus machining txheej txheem (ob txoj kev khiav) thawb lub abrasive los ntawm ob lub vertically opposite abrasive cylinders kom nws ntws rov qab mus rau hauv cov channel tsim los ntawm workpiece thiab fixture.Kev nkag thiab ntws ntawm abrasive mus rau hauv thiab los ntawm txhua qhov chaw uas raug txwv yuav ua rau muaj kev cuam tshuam abrasive.Lub extrusion siab yog tswj ntawm 7-200bar (100-3000 psi), haum rau txawv strokes thiab sib txawv lub sij hawm.

Cov khoom siv tau: Nws tuaj yeem lis 0.35mm microporous burrs, tsis muaj cov burrs thib ob yog tsim, thiab cov yam ntxwv ntawm cov kua dej tuaj yeem tswj txoj haujlwm nyuaj.

12 Sib nqus deburring

Sib nqus sib nqus yog tias nyob rau hauv qhov kev txiav txim ntawm cov hlau nplaum muaj zog, cov hlau nplaum abrasives ntim rau hauv magnetic teb yog npaj raws li cov kev taw qhia ntawm cov magnetic teb kab, adsorbed rau ntawm cov hlau nplaum los tsim "abrasive txhuam", thiab tsim ib tug tej yam siab rau. qhov saum npoo ntawm lub workpiece, thiab cov hlau nplaum yog tsav lub "abrasives".Thaum txhuam yog tig, nws khaws ib qho kev sib txawv thiab txav mus rau ntawm qhov chaw ntawm lub workpiece, thiaj li paub txog qhov ua tiav ntawm qhov chaw ntawm lub workpiece.

Nta: tus nqi qis, kev ua ntau yam, kev ua haujlwm yooj yim

Cov txheej txheem txheej txheem: grindstone, magnetic teb zog, workpiece ceev, thiab lwm yam.

13 Robot sib tsoo chav tsev

Lub hauv paus ntsiab lus zoo ib yam li phau ntawv deburring, tshwj tsis yog tias lub zog hloov mus rau hauv ib tug neeg hlau.Nrog kev txhawb nqa ntawm kev siv tshuab thiab kev siv tshuab quab yuam, kev sib tsoo yooj yim (hloov siab thiab ceev) tau pom, thiab qhov zoo ntawm cov neeg hlau deburring yog qhov tseem ceeb.

Piv nrog rau tib neeg, neeg hlau muaj cov yam ntxwv: txhim kho kev ua haujlwm zoo, txhim kho zoo, thiab tus nqi siab

Burrs hauv Kev Sib Tw Tshwj Xeeb Milled Parts

Nyob rau hauv milled qhov chaw, deburring yog complex thiab kim kim, raws li ntau burrs yog tsim nyob rau hauv txawv qhov chaw ntawm ntau thiab tsawg.Qhov no yog qhov uas xaiv cov txheej txheem kom raug kom txo qis burr loj dhau los ua qhov tseem ceeb dua.

Post lub sij hawm: Sep-29-2022